Maximising underwater situational awareness to enable safer and more effective Inspection Repair and Maintenance

How should unmanned vehicles deal with the harsh environmental conditions encountered underwater? What level of autonomy is needed to ensure safe and efficient autonomous operations? These and more questions are addressed within the SURE use case to realise the automation of underwater Inspection Repair and Maintenance tasks.

Deployment of Artificial Intelligence

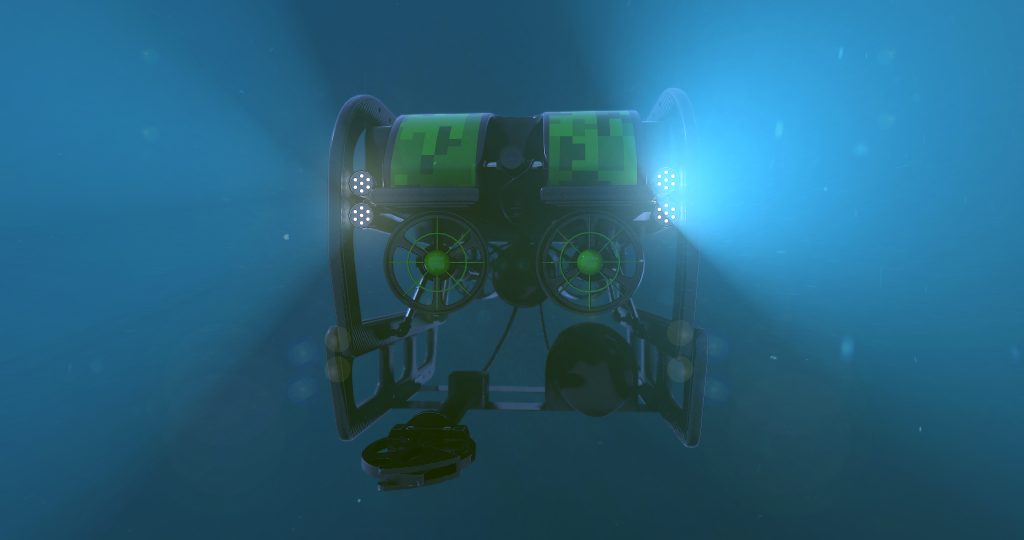

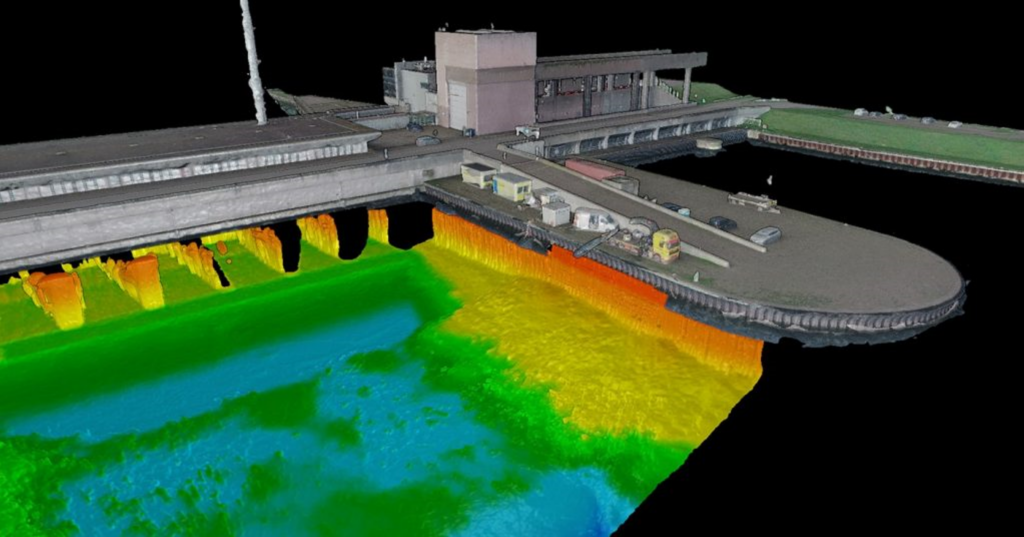

To ensure safe and efficient autonomous task execution, Autonomous Underwater Vehicles (AUVs) need to have sufficient knowledge of their environment, operator preferences and platform capabilities. When operating underwater, AUVs use a combination of sonar, camera and navigation sensors to perceive their surroundings and pinpoint their position. The deployment of AI supports the efficient interpretation of the large amount of multisensory data acquired using these sensors. In particular, the self-assessment of the navigation performance of AUVs is essential to ensure safe operations at sea. This is especially the case when operating in the vicinity of infrastructure or when other vessels are active in the operational area.

Artificial Intelligence methods can be used to reduce the buildup of navigational errors (drift). Currently used methods are often not accurate when it comes to taking into effect the influence of environmental parameters such as sea currents on the AUV’s dynamic behaviour. Current filtering methods use a single configuration of uncertainty parameters which often lead to inaccurate behaviour over varying environmental conditions. The drift evaluation can be improved by grouping the operational circumstances in clusters and using a specific uncertainty configuration for each of these individual cluster. In addition, AI can improve the autonomous planning capabilities to ensure that the planned work can be performed given the circumstances and to let the AUV decide when to connect to the human operator to renegotiate about the plan.

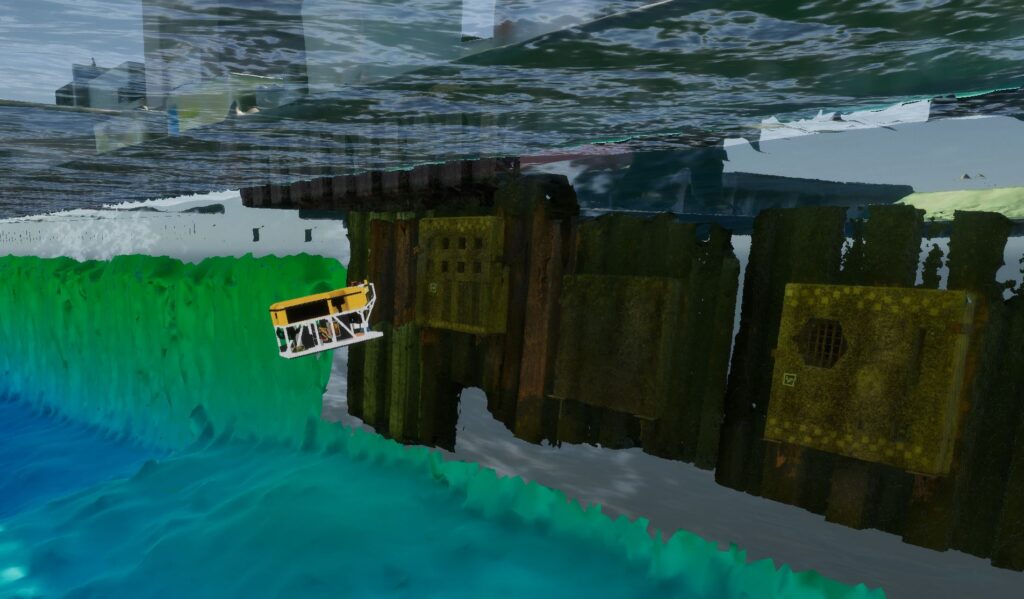

Figure below shows a simulated AUV track that operates in the multisensory virtual environment created based on data captured in the IJmuiden fieldlab. In this fieldlab, sensor and underwater vehicle performances are tested to accelerate development of autonomous inspection of underwater infrastructure. The virtual simulation environment can be used to train underwater vehicles to carry out inspection repair and maintenance task autonomously.

What challenge does it solve?

There is an increasing amount of inshore and offshore assets requiring Inspection, Repair and Maintenance (IRM). Divers carry out the majority of the IRM work, though there is a trend towards an increased usage of remotely operated underwater vehicles. The harsh operating conditions at sea pose a high risk for divers and limit the effectiveness of currently available unmanned vehicle solutions. To overcome the harsh operating conditions underwater, divers and unmanned vehicles need to be equipped with a wide variety of sensors to improve their navigation and perception capabilities. A combination of multiple sensor modalities is often needed to create a reliable operational picture. The real time interpretation of multi-sensor data remains however a serious challenge, limiting the effective usage of autonomous underwater vehicles for IRM work.

Approach

The SURE program utilises an agile approach to innovation, with valuable intermediate deliverables provided while still working towards the final objective in close corporation with partners throughout the maritime value chain. If you would like to learn more about the SURE program, please contact Eric Engelbrecht from TNO.

Partners

TNO works together with RWS and Boskalis towards a safer and more efficient Inspection Repair and Maintenance using Autonomous Underwater Vehicles and Artificial Intelligence. This project is connected to TNO’s Appl.AI program and is partly funded by the kick-start funds that the Netherlands AI Coalition received for research and development on AI applications.